Application of Quality Function Deployment to Improve Product Value under Green Target Costing Technique

– Applied research at the State Company for Textile Industries in Hilla –

– Plastic and woven bags factory in Hilla-

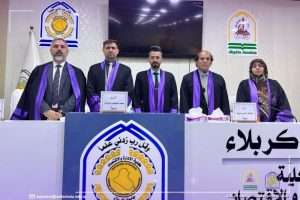

A letter submitted to the Board of the College of Administration and Economics, University of Karbala

It is part of the requirements for obtaining a Master of Science degree in Accounting

from the student

Elham Ali Mahdi Al-Kinani

Supervised by

Dr.Hussam Muhammad Ali Al-Owaid

Abstract

The green target cost at this time is one of the important concepts, as it provides a solution to the accumulated problems facing Iraq, including the rise in the number of cancerous diseases, one of the reasons for which is the lack of orientation towards the use of environmentally friendly products, as a result of the lack of environmental awareness and the perceived high cost of its production, which is referred to as an obstacle In front of companies, which prevents their production and spread in the market.

The research aims to provide a theoretical framework for the dissemination of the quality function, the green target cost, and the management of value engineering as a supportive methodology to achieve the target reduction.

To achieve the goal of the research, the method of analyzing plastic and woven bags laboratory data was adopted, as well as visits, field coexistence, interviews with officials and workers, accounting records and financial reports.

The researcher reached several conclusions, the most important of which is that the application of the green target cost and the dissemination of the quality function and value engineering as a supportive methodology contribute to improving the value of the product, which leads to an increase in sales, which is reflected in the profitability of the company in the long and short term, so the most important recommendations are the need to exploit the application of the target cost technique And using the deployment of the quality function and value engineering as a supportive methodology for the presence of the necessary capabilities for its application, including machines, equipment, and skilled personnel.